Asphalt Pro Article June 2012

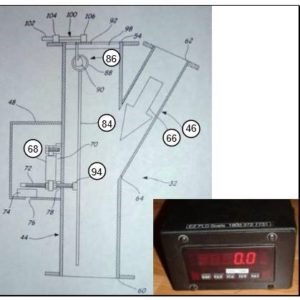

RAS Solids Impact Flow Meter

Recycled Asphalt Shingle Weighing Applications get a boost from continuous weighing. No matter what you call it, Solids Impact Flow Meter or Dry Flow Meter or Impact Plate or Mass Flow Meter, Ez-Flo Scales gets the job done.

If you wish to trim asphalt cement (AC) costs while keeping waste material out of landfills, you’ve probably looked into the recycled asphalt shingle (RAS) availability in your area. With the quality control (QC) issues of bringing in clean RAS and having it ground to the finest size you can get, you may have run into the challenge of weighing that material accurately throughout the mix design and mix production phases. Not to worry. Producers in the field have met with some challenges when it comes to handling RAS and they have tips and advice to help their peers ensure a quality mix for customers, owners and agencies. Let’s begin looking at this topic by addressing some of the QC aspects to watch for when working with a finely ground recycle material such as RAS. First, remember that the amount of recycled AC you get out of RAP is a different percentage than what you get out of RAS. Even the amount of AC in RAS can vary from 15 to 35+ percent. That means your plant operator has much to track when it’s time to produce mix with recycle in it. Of course plant manufacturers and controls OEMs are part of the solution.

“Initially, it’s very important to know the difference between excess manufacturing tabs on the one hand and recycled shingles from a roof tear-off on the other hand. These two types of shingles must be handled, fed, metered, proportioned and blended in different ways. For example, your RAP bin is separate from your RAS bin. If that’s the case, shouldn’t you also separate never-used shingles from worn-out shingles?” The big question producers in the Midwest have asked of Clarence Richard, proprietor of Clarence Richard Co., Hopkins, Minn., concerns measuring what comes out of the separate bins. What he discovered in working to resolve their measuring issue was an accuracy issue. Quality control of RAS needs a delicate touch. “Most producers are trying to weigh RAS using the existing RAP feeder system that they have without making any improvements,” Richard said. “There are a few reasons that producers will want to update existing equipment for RAS.

First, RAS carries a lot of AC in it. When accuracy is off, the AC content is affected by the error more than when RAP’s accuracy is off.” Richard’s second observance should encourage producers to look not only at multiple bin use for multiple products, as proponents of fractionated RAP have said for years, but also to look at multiple scales that the control house can read. His third should encourage producers to look at equipment shape. “Second, sometimes producers use multiple bins in series with a RAP s with RAP in one of the bins and RAS in another,” Richard continued. “They can’t be sure how much is coming out of either bin at any given time. The RAP conveyor was built for heavier TPH flow rates (25 to 125 TPH) of RAP productions. Current RAS rates require weighing product from 5 to 25 TPH. That’s a big difference. The RAP scale system (conveyor included) was not built to accurately weigh material at such a low flow rate. “Third, when you have multiple bins in series with a RAP scale system, there’s no way for the blending control to adjust for bin speed when one of the RAP bins or RAS bin clogs up, or density is changed. And density can change plus or minus 15 percent.

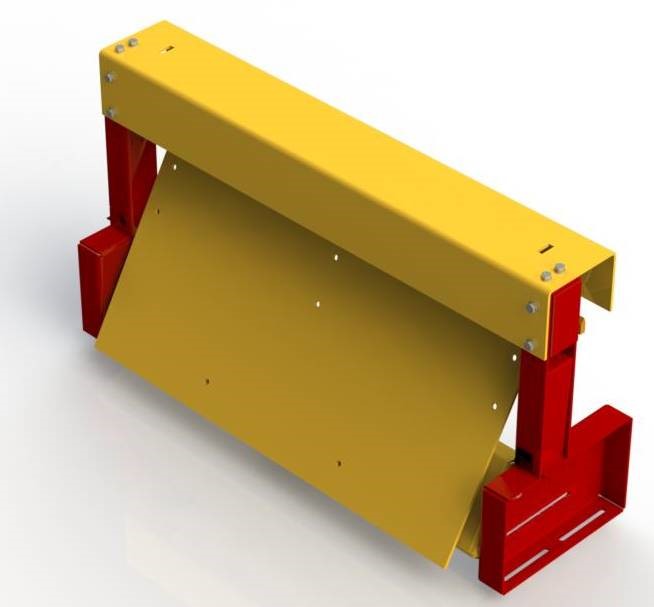

Some belt scale manufacturers advise against using their scale to weigh light-loaded products for such a critical application.” To address weighing RAS separately, Richard brought up the EZ-Flo continuous weigh flow scale (Impact Plate) that his company manufactures. To address flow and controls, a variety of sources discussed controls and equipment use. The flow scale from Clarence Richard Co. works much like a belt scale except it doesn’t need a tachometer. It already “knows” the speed of the material passing through it is constant—gravity. The solids impact flow meter reads the rate of material flow as it impacts the front face of the impact plate. The rate reading, in TPH, indicates how fast material is passing through the impact flow meter and produces an output signal useful for blending materials. The totalizer reading, in tons, is used for calibrating the scale, cross-checking accuracy, inventory control and producing a signal capable of batching product. The flow scale impact plate is mounted 6 inches away from the end of the belt feeder head pulley to measure the RAS flow rate. Dual recycle bins often mean the producer fractionates his RAP and treats it with the same care he treats virgin aggregate. That’s an excellent practice. When he decides to use one of the recycle bins for a much finer product like RAS, quality control management needs to take a step up.. Keep in mind that continuous weigh scales and metering instruments should be checked for accuracy. The accuracy of the check is only as good as the resolution of the instruments being used, the size of the sample and the sampling method. An 8-ton sample is gathered, which is better than a 4-ton sample. The procedure was to collect material in a truck after the material had traveled more than 100 feet of conveyor and through a scalping screen.

Clarence Richard suggests producers place a strip of conveyor belt or similar material alongside the EZ-Flo Solids Impact Flow Meter to prevent wind from affecting its delicate operation. Of course, you’ll want to add that encumbrance after you get the scale into this tight space.

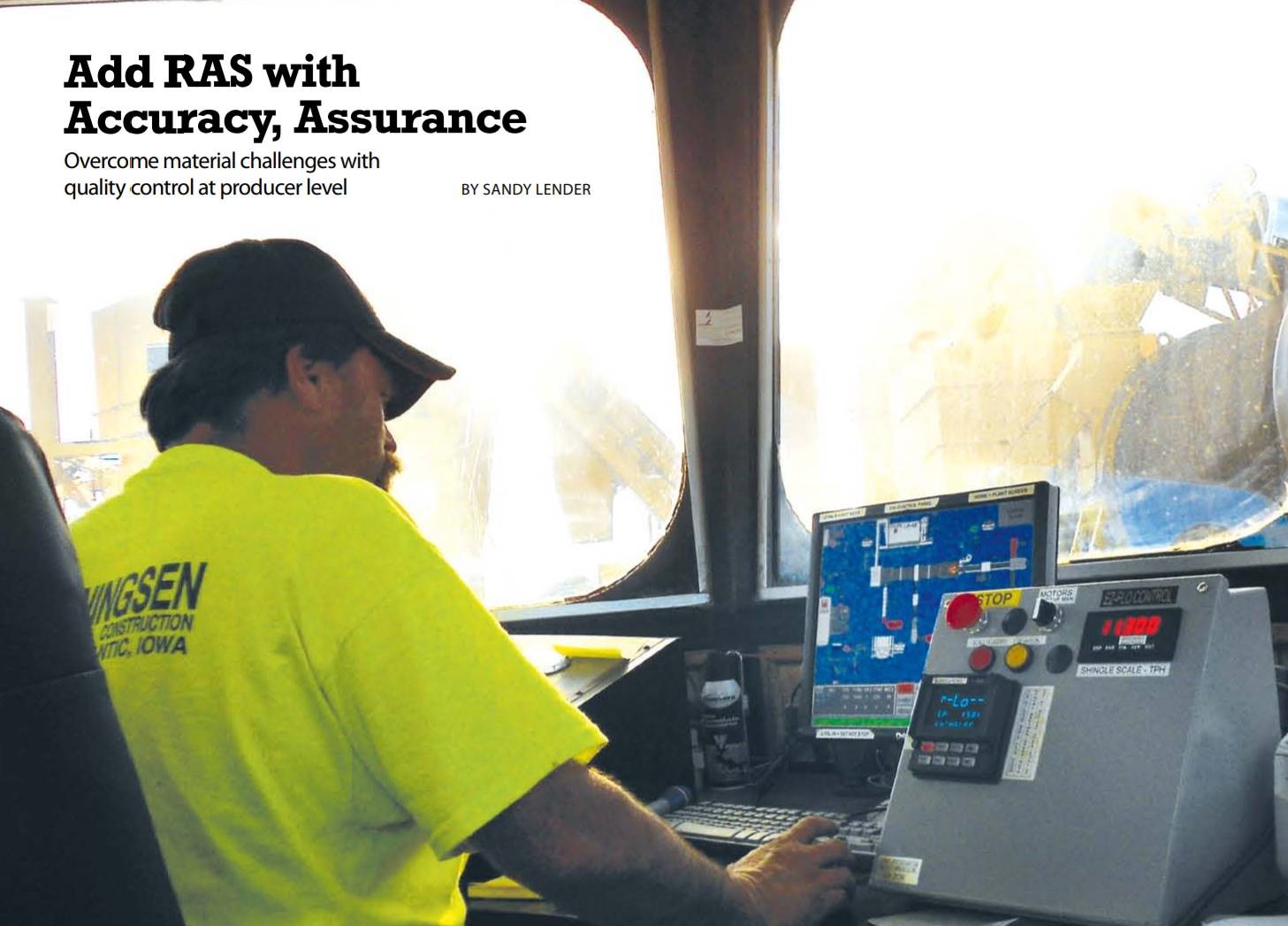

Henningsen Plants Superintendent A.J. Dennis Campbell points out the installation of the EZ-Flo Dry Solids Flow Meter. A.J. Dennis Campbell, plants superintendent for Henningsen Construction, Atlantic, Iowa, shared that he had concerns when his company won a 60,000-ton job that required about 4 percent shingles. The job was in Iowa, but on the Illinois border, so two groups took an interest when Campbell gave the go-ahead for an EZ-Flo Solids Impact Flow Meter to be designed, built and delivered in four weeks. He wanted an accurate means of weighing RAS material as it discharged from the RAS feeder belt to the collector belt. The distance between the RAS feeder head pulley and the RAP tail pulley— and both of their support structures— is 20 inches. The distance between the bottom of the feeder belt and the center of the collector belt was 12 inches. The troughing rollers used up part of that 12-inch space. The RAP bins also have bin support structure and bin feeder conveyor drive pulley-sprocket arrangement on one side of the bin and the loader ramp barricading access to the confined space. That meant the team assembled the scale inside the confined space as much as possible.

With the careful operation done, the EZ-Flo can be used at the Henningsen operation for fine RAP and RAS monitoring. An operator can slide the scale out of the flow when using the bin for RAP. Henningsen Plant Manager Duane Updike observed flow rate changes during production with the EZ-Flo in place. The impact scale located in the control house reads in real time and would normally be monitored by the plant computer. “Plant computers are programmed to either compensate for the AC when the RAP scale deviates from a set point or to increase or decrease both feeder bin speeds,” Richard reminded us. “Either way, one scale is not enough.

Now, the mix producer has the option of weighing the RAS and controlling that bin or the AC being added to the mix. The same RAS rate signal being used to control for the RAS can be subtracted from the RAP belt scale—which is weighing both RAS and RAP—to indicate the actual RAP TPH flow rate.” This means the plant computer can use RAP deviation information to adjust the oil being added to the mix or the RAP feeder speed. “Contractors should give a heads up to their blending control manufacturers about the changing requirements they’re asking of their blending controls,” Richard said. “Today’s blending controls aren’t usually set up with the software to accept another scale input or two to monitor the flow with a continuous weigh RAS scale and, consequently, control the flow from that scale information.” That means it may be time to contact your controls OEM to get analog inputs for a new scale. Jim Richwine, director of engineering for Libra Systems, pointed out the importance of connecting new technology with new technology. “Most plant operators open the gate on RAP bins much wider than would normally be done for volumetric control. They do this to prevent bridging, but in the process, they hinder traditional volumetric control because the material is then not cut by the gate. Instead, the material pours from the bin and the amount produced by the bin for each revolution of its belt actually varies as the belt speed changes. So, the old-style control systems that used a single ‘pounds per tach pulse’ calibration for the bin became inaccurate at different speeds." Richard concurs that multi-point calibration is better than single-point volumetric calibration, but he says that volumetric control of any type is unacceptable for RAS. The demonstration mentioned previously proved that RAS controlled volumetrically was wandering all over the map. “RAS density changes plus or minus 15 percent,” Richard reminded us. “Therefore the accuracy of weighing material volumetrically is plus or minus 15 percent.” Any QC manager can tell you what that range does to voids.

Asphalt Pro January 2012 by Sandy Lender

Impact Flow Meter Controls the Uncontrollable

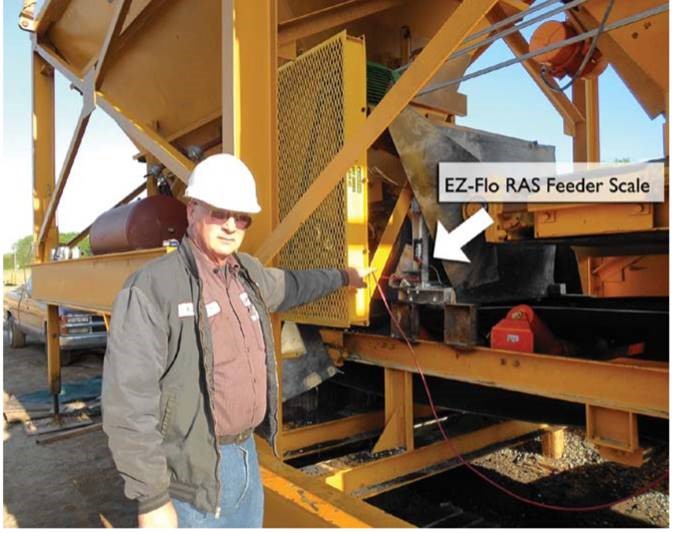

Keep Baghouse Surges from Disrupting Mix Quality. Elam Construction managers go ghost busting to solve fluctuating problems.

Consider for a moment that your quality control (QC) team has perfected a mix design for a state project. Everything is seamless from the aggregate to the binder to the percentage of RAP. The test strip your paving crew placed on the back lot gave beautiful compaction numbers. Then the department of transportation quality assurance inspector ran a test and your air voids were all wrong. Your crew paved an extra test strip and couldn’t get density to save their lives. What on earth went wrong? Jeremy Dade is the plants manager for Elam Construction in Grand Junction, Colo., and told a similar story. “We’d either have too much 200s in the mix or not enough.” It took more than a year of trial and error to realize the problem came from the baghouse fines. “We even turned the baghouse return off,” Dade said. Nothing seemed to give them a consistent result. Instead, they saw a big swing of 1.2 to 1.7 tons per hour (TPH) in the 200s, Dade said.

By installing a device from Clarence Richard Co. that weighs and meters the dust going into the drum, the plant personnel slowed the rate to a steady 4.2 TPH, according to Dade. Elam Construction personnel had found a problem with the sags and surges in the baghouse’s normal operation. A typical pulse-jet baghouse has about 64 rows of 10 to 15 bags that pulse three rows at a time on a timer. The dust that falls to the bottom of the baghouse gets augered out in surges, thus the fines returning to the drum move in surges. This gives varying amounts of fines in your mix design. A rotary air baghouse could be considered “worse” as it can stop sending material for up to a minute at a time. But a plant operator can’t blame the baghouse. It’s operating as it was intended. “The primary purpose of the baghouse is for emission or pollution control from the plant process, Some contractors over the years have used the baghouse hopper as a temporary holding device to feed the fines to the plant. Most producers today have much more sophisticated feeding and metering devices to properly proportion the dust/fines back to the material feeding and mixing operation.”

David Fife, the QC manager for Elam Construction, spelled out his experience in detail. “There are many aspects as to how dust effects mix designs,” Fife began. “I can remember standing next to a hot plant several years ago with a Colorado Department of Transportation (CDOT) inspector trying to figure out why the properties of the mixture where fluctuating. I hadn’t been making changes in the percentages of materials at the hot plant, and we religiously had run crusher control on the aggregates as they had been manufactured. I told the inspector that I was chasing ghosts. Every time I had my fingers on the problem it would disappear and show up again on the other side of the specification. “At that time I had a pretty good idea this problem was based on dust but I couldn’t put my finger on exactly why it was appearing then disappearing without changes at the plant,” Fife continued. “I had run enough gradations on the stockpiles to know the crushing or inconsistent materials did not create the problem. Over the next several years, through trial and error I found it was not a ghost; it was fluctuation in the dust being returned to the mixture via the Baghouse.

“To sum up the problem, a dust feeder that is allowing the dust to be returned into the mixture in sags and surges is creating a mixture that does not have a constant demand for oil. In other words, when excessive dust is being pumped into the mixture the Voids in Mineral Aggregate (VMA) is generally decreased, creating less room in the mixture for oil. When the dust is being starved in the mixture, the VMA generally is increased creating a mixture with more room for oil. With the VMA floating around, a mixture with a varying demand for oil is being created. “The hot plant has no way to track the problem, and continues to add consistent oil. With the percent oil staying the same and a changing VMA, the voids fluctuate with the changing VMA. As a result to the fluctuation in the mixture’s voids, the crews in the field are continually adjusting the roller patterns to achieve the required density. After all, density is just a measurement of in place voids. This problem is often magnified by volumetric tests being produced by the testing department, and adjustments to the mixture being made based on sags or surges in the Baghouse. This custom dust runaround was built to prevent the surge of baghouse fines.

“As all of us in the asphalt industry have experienced, the key to producing quality asphalt mixtures is to be able to find the right combinations of materials, and consistently produce at these combinations. The search for consistency is easier created in the lab than produced in the field. We have many obstacles to overcome when attempting to recreate every ton exactly as the prescribed mix design calls for. A system that supplies a continuous flow of dust to the mixture helps overcome one of these obstacles,” Fife said. Fife is no longer chasing Ghosts. He now uses the Ez-Flo Continuous Weigh Control System with Solids Impact Flow Meter as manufactured by Clarence Richard Co. The scheme Elam used on their portable plants is significantly different than what Richard suggests for stationary plants. Surge control normally requires the addition of an auger and storage bin. Richard eliminates the need for a surge bin (silo) and associated auger for portable plants with a flow scale being fed by a variable feed auger. When in the dust rejecting mode, the dust surges move from feeding the mix process to feeding the reject pit while the amount of dust being returned to the mix is measured, controlled and fed evenly to the mixer.

The system doesn’t need a surge bin because sags and surges are eliminated by the use of the flow scale and large variable speed auger feeding the mixer. This saves on the purchase, setup and maintenance of the bin. Please take care that no body falls to their instant, unpleasant death if they fall into a full open pit.

The large volume auger substitutes the need for a bin. When the auger is adequately sized, the automatically operated auger can eliminate the sags by speeding up during the times the baghouse is not delivering enough dust. Elam Construction’s Dade operates the system differently depending on whether or not the job mix calls for dust to be rejected. If dust is not rejected, the surge elimination mode returns all the dust back into the mix evenly. In the end, Elam Construction mixes can remain consistent throughout production with metered and monitored fines introduction while the baghouse continues its proper and expected operation. This keeps the QC team and the paving team working with something they can rely on throughout production.

“To sum up the problem, a dust feeder that is allowing the dust to be returned into the mixture in sags and surges is creating a mixture that does not have a constant demand for oil.” —David Fife, QC Manager for Elam Construction

When surge bins are required, use what you want and reject the difference. When using all your dust, the bigger the bin, the more you can smooth out the larger surge-sag swings..

Here’s How with Solids Impact Flow Meter Works: Material slides down the EZ-Flo flow meter’s feed throat and impacts a suspended plate (Impact Plate). The material impact force on the plate is transferred to a load cell, which converts the gravimetric force to digits on the readout. It displays both the flow rate in tons per hour (pounds per minute, etc.) and the tons of material that has passed through the scale since the totalizer was last zeroed.